Summary

Choosing a knife can seem overwhelming given the countless options available. But quality isn't a matter of luck — it results from specific technical choices. This guide reveals the 7 fundamental criteria to ensure you never make a mistake again. We’ll cover the type of steel, the crucial importance of heat treatment, the blade geometry (grind), assembly robustness, handle ergonomics, attention to finish details, and the quality of the factory edge. By mastering these points, you'll be able to evaluate any knife, make informed purchases, and invest in a tool that will serve you for many years. This is a knifemaker’s expertise made accessible to you.

Key Points for Quick Reading:

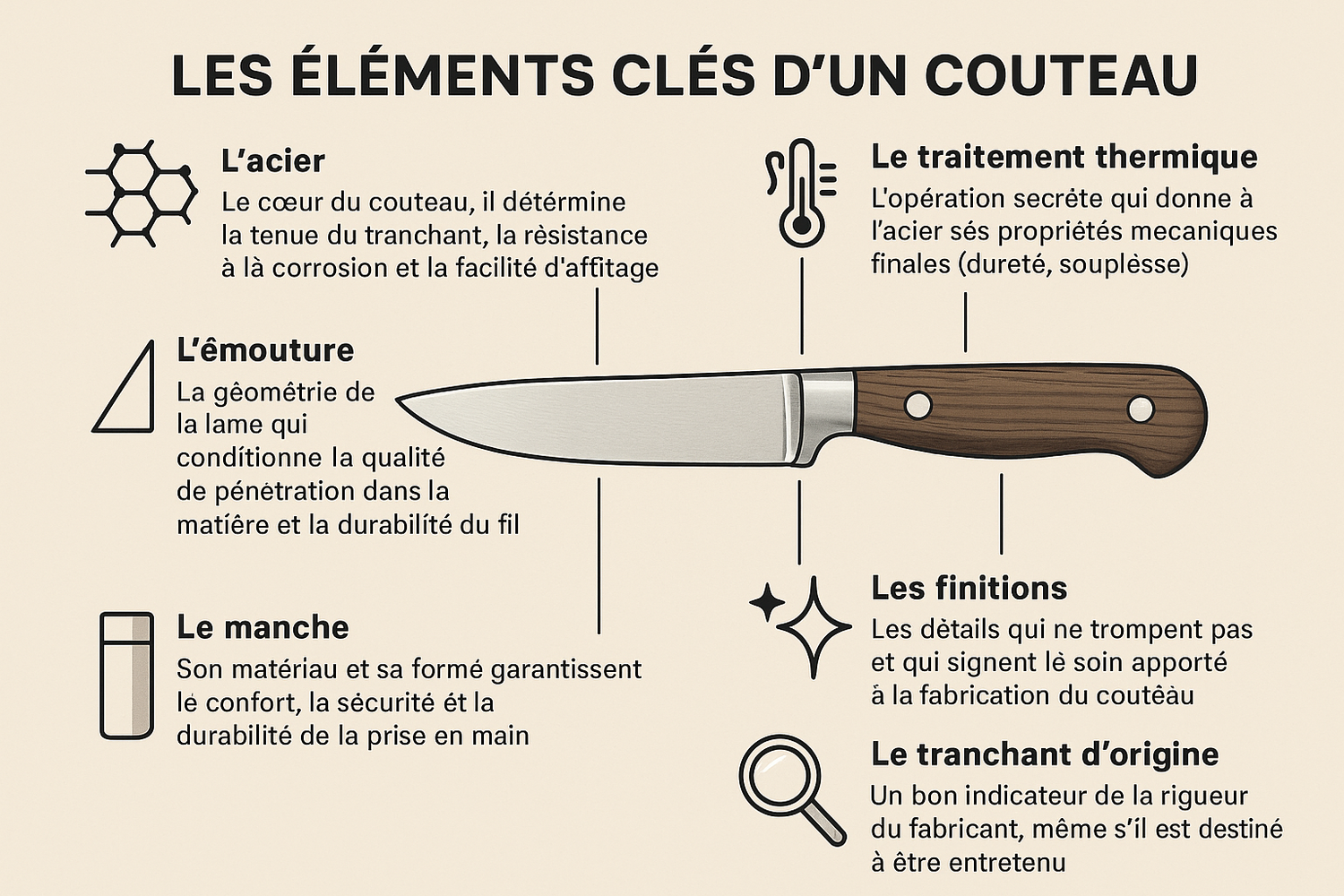

- Steel: The heart of the knife, determining edge retention, corrosion resistance, and sharpening ease.

- Heat treatment: The secret process that gives steel its final mechanical properties (hardness, toughness).

- Grind: The blade’s geometry that affects cutting performance and edge durability.

- Assembly: The construction method (notably the tang for fixed blades) ensuring strength and balance.

- Handle: Its material and shape ensure comfort, safety, and durability.

- Finishes: The details that reflect the care and craftsmanship put into the knife.

- Factory edge: A key indicator of the manufacturer's attention to detail, even though maintenance will be required.

Is Steel the Most Important Factor?

Yes — steel is the most critical component determining a knife's performance. It's the raw material that defines how well a knife cuts and how long it stays sharp.

Steel isn't a single material; it's an alloy of iron and carbon, with additional elements (chromium, molybdenum, vanadium, etc.) added to give specific properties. Broadly speaking, there are two main families:

- Stainless steels: Rich in chromium (more than 13%), they offer excellent corrosion resistance. This makes them practical and easy to maintain. At TB 1648, for example, we use Nitrox stainless steel, known for its outstanding balance of edge retention, rust resistance, and ease of sharpening.

- Carbon steels: Containing less chromium, they can rust if not properly cared for. However, they are often easier to sharpen and can achieve exceptionally fine edges, highly valued by purists.

A quality steel must strike the right balance between three key properties: hardness (to retain the edge), toughness (to prevent breakage), and corrosion resistance.

Why Is Heat Treatment a Key to Quality?

Heat treatment is the crucial step that transforms a simple piece of steel into a high-performance blade. Exceptional steel poorly treated will result in a mediocre knife.

This process involves heating the steel to a precise temperature (the austenitizing point), rapidly cooling it (quenching), and then reheating it at a lower temperature (tempering). This complex thermal cycle, mastered by skilled knifemakers, refines the steel's molecular structure to achieve the desired hardness. Hardness is measured on the Rockwell scale (HRC). A quality pocket knife typically falls between 56 and 60 HRC. Below this, the edge dulls quickly; above, it may become brittle.

At TB 1648, this expertise is central to our manufacturing process, ensuring every blade reaches the optimal hardness for its intended use.

How Does Blade Geometry (Grind) Affect Cutting?

The grind — how the blade tapers from spine to edge — determines how easily the knife penetrates material and how durable its edge is.

Think of splitting a log with a flat piece of metal: it’s impossible without a wedge shape. The grind is that wedge. Several types exist:

- Flat grind: The most versatile, offering a good balance between sharpness and strength.

- Hollow (concave) grind: Delivers a razor-sharp edge but is more delicate.

- Convex grind: Extremely robust, ideal for camp or survival knives.

A quality grind should be symmetrical and even. Run your fingernail from the spine to the edge — you should feel no irregularities or sudden changes.

How Do Assembly and Construction Ensure Strength?

The assembly method guarantees the cohesion between blade and handle, ensuring user safety and knife longevity.

For fixed-blade knives, the key feature is the tang — the part of the blade that extends into the handle. The ideal construction is a full tang, where the tang matches the handle's shape and is visible along its entire contour. This is the strongest and most balanced design.

For folding knives, quality is judged by the locking mechanism (liner-lock, frame-lock, back-lock, etc.), which should be firm with no play, and by the pivot axis. A quality folding blade should sit perfectly centered between the liners when closed.

How Important Are Handle Material and Ergonomics?

Critically important. The handle is your point of contact with the tool. Its comfort (ergonomics) and durability (material) are essential for safe, enjoyable use.

Several materials are used, each with its advantages:

- Wood: Warm, elegant, and unique (each grain pattern is different), but requires some maintenance.

- Composites (G10, Micarta): Extremely resistant to water, shock, and temperature changes. They offer excellent grip.

- Metal (stainless steel, titanium): Strong and modern, but can feel slippery or cold to the touch.

Beyond the material, hold the knife in your hand. It should fill your palm comfortably, with no pressure points. Good ergonomics prevent fatigue and accidents.

What Do Finishes Reveal About Knife Quality?

Finishes are the manufacturer's signature. They reflect the time and care invested and are an excellent indicator of overall quality.

Inspect the knife closely. Look for:

- Fit: There should be no gaps between the different parts (blade and handle, scales and liners, etc.).

- Polish: Metal surfaces should be evenly polished with no residual machining scratches.

- No sharp edges (except the cutting edge): The spine, handle edges, and other parts should be slightly rounded for comfort.

Should a Quality Knife Be Razor-Sharp Out of the Box?

Yes — a razor-sharp factory edge reflects attention to detail and respect for the customer, even though the edge will require maintenance over time.

A manufacturer that has invested in quality steel, precise heat treatment, and a carefully executed grind will not neglect the final step. The paper test is a good indicator: the blade should slice cleanly through a sheet of paper with no tearing or effort. This proves correct sharpening angles and a clean edge — a solid foundation for all future maintenance you’ll perform.

Frequently Asked Questions (FAQ)

- What is a "full tang" construction?

It means the blade’s metal extends through the entire length and width of the handle — the strongest construction for fixed-blade knives. - What does HRC mean?

It stands for "Hardness Rockwell scale C" — the standard unit of measurement for steel hardness after heat treatment. - Is a heavier knife better?

[You can complete this FAQ entry according to your content.]